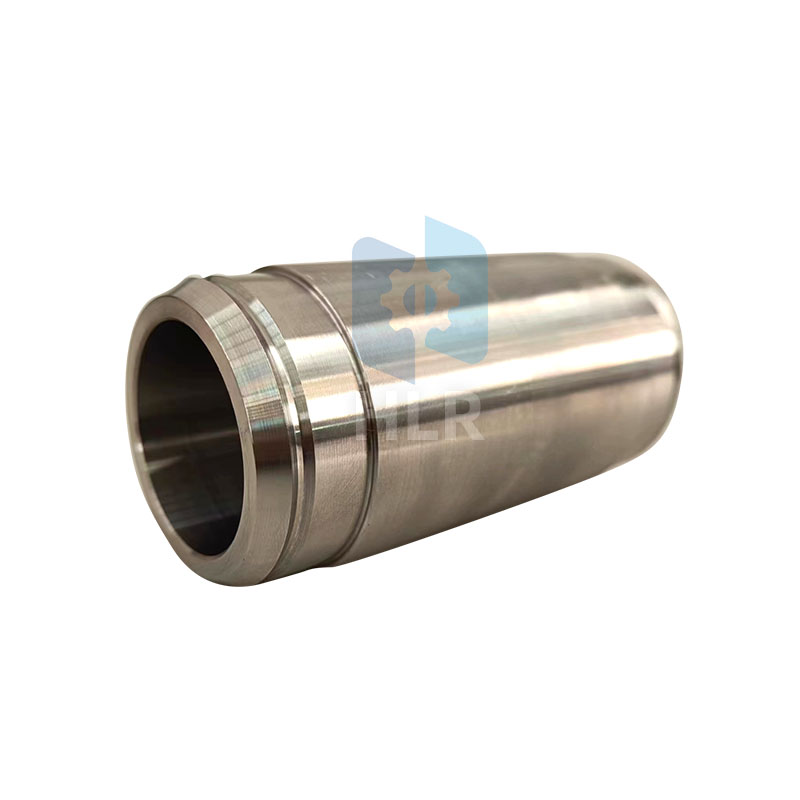

Unveiling the Powerhouse Component: Sealed Stainless Steel Cylinder Liners

2024-02-20

In the intricate world of engine design, where every component plays a crucial role in achieving optimal performance, the sealed stainless steel cylinder liner stands out as a powerhouse. Often overlooked but indispensable, this component serves as the backbone of combustion engines, ensuring durability, efficiency, and reliability. Let's delve into what exactly a sealed stainless steel cylinder liner is and the pivotal role it plays in engine design.

Understanding Sealed Stainless Steel Cylinder Liners

A sealed stainless steel cylinder liner, also known as a sleeve, is a cylindrical component inserted into the engine block's cylinder bore. It forms the inner wall of the cylinder, providing a smooth and durable surface for the piston's movement. The term "sealed" indicates that these liners are designed to minimize leakage of gases and fluids between the cylinder wall and the liner, crucial for maintaining optimal compression and preventing contamination of lubricants.

The Role in Engine Design

1. Durability and Wear Resistance: Stainless steel, renowned for its strength and corrosion resistance, is the material of choice for cylinder liners. Its exceptional durability ensures prolonged engine life, even under harsh operating conditions.

2. Heat Dissipation and Thermal Stability: Sealed stainless steel cylinder liners excel in dissipating heat generated during combustion. Their high thermal conductivity and stability help maintain consistent operating temperatures, preventing overheating and thermal expansion issues.

3. Precision Engineering for Tight Tolerances: Engine efficiency relies on maintaining tight tolerances between the piston and cylinder wall. Sealed stainless steel cylinder liners are manufactured with precision engineering techniques to achieve these critical tolerances, minimizing friction and optimizing performance.

4. Reduced Friction and Improved Fuel Efficiency: The smooth surface finish of stainless steel liners, coupled with their excellent lubrication retention properties, reduces friction between the piston rings and cylinder wall. This translates to improved fuel efficiency and reduced wear on engine components.

5. Sealing Integrity: The sealing mechanism of stainless steel cylinder liners ensures effective containment of combustion gases and prevents oil contamination. This is vital for maintaining optimal compression ratios and minimizing emissions, contributing to compliance with environmental regulations.

6. Adaptability to Engine Designs: Sealed stainless steel cylinder liners are versatile components that can be tailored to suit various engine configurations and performance requirements. Whether in high-performance sports cars or heavy-duty industrial machinery, these liners offer adaptability and reliability across diverse applications.

Conclusion

In the intricate ecosystem of engine design, the sealed stainless steel cylinder liner emerges as a cornerstone of performance and reliability. Its robust construction, superior materials, and precision engineering make it an indispensable component, ensuring efficient power generation while withstanding the rigors of demanding operating conditions. As automotive and industrial technologies continue to evolve, the sealed stainless steel cylinder liner remains a steadfast ally in the pursuit of engineering excellence and innovation.