Unveiling the Alchemy of Energy: How Hydrogen Fuel Cell Electrolyzers Transform Electrical Energy into Hydrogen Gas

2023-12-15

Introduction:

In the quest for sustainable energy solutions, hydrogen has emerged as a promising contender, and at the heart of this hydrogen revolution lies a fascinating process—the workhorse known as the hydrogen fuel cell electrolyzer. In this exploration, we delve into the intricacies of how a hydrogen fuel cell electrolyzer performs its alchemy, converting electrical energy into the clean and versatile fuel of the future—hydrogen gas.

The Fundamental Process:

At its core, the operation of a hydrogen fuel cell electrolyzer is grounded in the principle of electrolysis, a process where an electric current prompts a chemical reaction. In the case of hydrogen production, water (H₂O) is the raw material, and the objective is to split it into its elemental components: hydrogen (H₂) and oxygen (O₂).

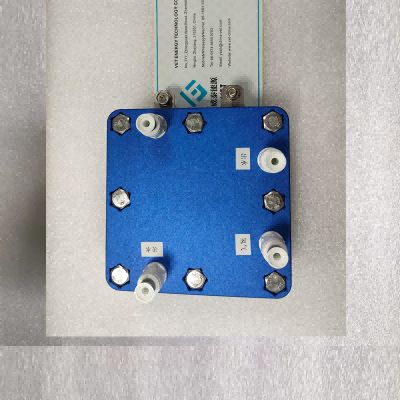

Key Components of a Hydrogen Fuel Cell Electrolyzer:

1. Electrolyte: The process begins with an electrolyte—a substance that facilitates the movement of ions. Common electrolytes include alkaline solutions, proton exchange membranes (PEMs), or solid oxide materials, depending on the type of electrolyzer.

2. Anode: Positioned at one end of the electrolyzer, the anode is where the oxidation half-reaction occurs. Here, water molecules lose electrons to form oxygen gas and positively charged hydrogen ions (protons).

3. Cathode: At the opposite end sits the cathode, where the reduction half-reaction unfolds. Hydrogen ions migrate to the cathode, where they gain electrons and transform into hydrogen gas.

4. Electrodes: Conductive materials, typically composed of metals like platinum or other catalysts, serve as the interface for electron transfer during the redox reactions.

The Electrolysis Journey:

1. Application of Electrical Voltage: As electrical voltage is applied across the electrolyzer's anode and cathode, water molecules near the anode undergo oxidation. Electrons released in this process travel through an external circuit.

2. Oxidation at the Anode: At the anode, water molecules split into oxygen, electrons, and protons. The oxygen is released as a byproduct, while the protons migrate through the electrolyte to the cathode.

3. Reduction at the Cathode: Meanwhile, at the cathode, protons combine with electrons arriving from the external circuit to form hydrogen gas.

4. Hydrogen Collection: The produced hydrogen gas is then collected for various applications, such as energy storage, fuel for fuel cells, or industrial processes.

Types of Hydrogen Fuel Cell Electrolyzers:

There are various types of hydrogen fuel cell electrolyzers, each with unique features. Alkaline electrolyzers use liquid alkaline electrolytes, PEM electrolyzers employ solid polymer electrolytes, and solid oxide electrolyzers utilize high-temperature solid oxide materials.

Efficiency and Environmental Impact:

Hydrogen fuel cell electrolyzers are recognized for their efficiency in converting electrical energy into hydrogen gas. Depending on the type, efficiencies can range from around 60% to 80%. Furthermore, the process produces only oxygen and hydrogen gas as byproducts, making it a clean and environmentally friendly method of hydrogen production.

Conclusion:

The alchemy of a hydrogen fuel cell electrolyzer, with its dance of electrons and protons, embodies a transformative force in the energy landscape. As we witness the surge in interest and investment in hydrogen technologies, the electrolyzer stands as a key enabler, converting electrical energy into a clean, versatile fuel that holds the potential to power our sustainable future. In this alchemical journey, the hydrogen fuel cell electrolyzer takes center stage, ushering in a new era where electrons pave the way for hydrogen's ascent as a cornerstone of the renewable energy revolution.