Unveiling the Advantages of Steel in Metal Stamping

2024-03-13

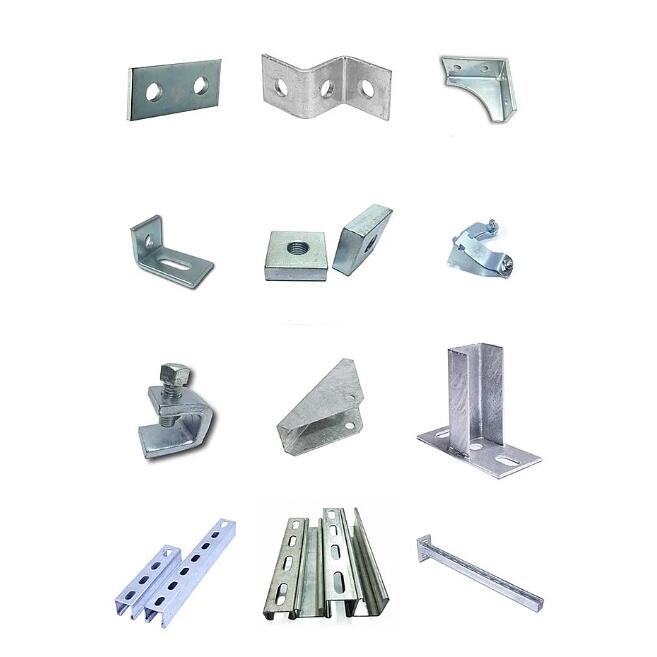

Metal stamping is a versatile manufacturing process widely used across industries for producing a vast array of components. Among the various materials employed in metal stamping, steel stands out as a preferred choice for many applications. In this blog, we'll explore the numerous advantages of using steel for metal stamping, highlighting its versatility, durability, and cost-effectiveness.

1. Strength and Durability:

Steel is renowned for its exceptional strength and durability, making it ideal for applications requiring robust and long-lasting components. Steel stamping provides high structural integrity and resistance to wear, corrosion, and impact, ensuring reliable performance even in harsh operating environments.

2. Versatility:

Steel's versatility allows for the fabrication of a wide range of components with diverse shapes, sizes, and complexities. Whether it's intricate automotive parts, precision electronic components, or heavy-duty industrial components, steel stamping can accommodate various design requirements and specifications with ease.

3. Cost-Effectiveness:

Steel stamping offers significant cost advantages compared to alternative manufacturing processes such as machining or casting. The high-speed production capabilities of steel stamping, coupled with the ability to utilize coil or sheet metal stock efficiently, result in lower material waste and reduced production costs, making it a cost-effective solution for high-volume production runs.

4. Design Flexibility:

Steel stamping provides designers with unparalleled design flexibility, allowing for the creation of complex geometries and intricate features with tight tolerances. The stamping process enables the formation of bends, contours, holes, and embossments in steel sheets or coils, enabling the production of customized components tailored to specific application requirements.

5. High Precision and Accuracy:

Steel stamping processes offer exceptional precision and accuracy, ensuring consistent dimensional tolerances and tight part-to-part repeatability. Advanced tooling and die designs, coupled with state-of-the-art stamping equipment and technologies, enable the production of high-quality components with minimal variation and defects.

6. Speed and Efficiency:

Steel stamping boasts rapid production speeds and high throughput rates, allowing for the efficient manufacture of large quantities of components within short lead times. The automated nature of steel stamping operations, combined with advanced die changeover techniques and production optimization strategies, maximizes efficiency and productivity in manufacturing environments.

7. Material Options:

Steel stamping encompasses a wide range of steel grades and alloys, each offering unique properties and characteristics suited to specific applications. From mild steels to high-strength, heat-treated alloys, steel stamping provides access to an extensive selection of materials to meet diverse performance requirements and environmental conditions.

8. Surface Finish Options:

Steel stamping components can be finished to achieve various surface textures, coatings, or treatments to enhance functionality, appearance, and performance. Options such as plating, painting, powder coating, and surface treatments offer corrosion resistance, aesthetic appeal, and improved surface hardness, further extending the versatility and utility of steel components.

9. Environmental Sustainability:

Steel is a highly recyclable material, with the vast majority of steel used in manufacturing being recycled and reused. Steel stamping processes contribute to environmental sustainability by minimizing material waste, energy consumption, and environmental impact compared to alternative manufacturing methods, aligning with modern sustainability goals and initiatives.

In conclusion, the advantages of using steel for metal stamping are undeniable, encompassing strength, durability, versatility, cost-effectiveness, design flexibility, precision, efficiency, material options, surface finish options, and environmental sustainability. As a preferred material choice in a wide range of industries, steel stamping continues to drive innovation, efficiency, and excellence in manufacturing, offering unmatched performance and reliability for diverse applications.