Understanding Automatic Spot UV Coating Machines: How They Enhance Print Finishing

2025-02-22

In the world of high-quality printing, achieving a professional and visually appealing finish is just as important as the design itself. One of the most effective ways to add value to printed materials is through Spot UV coating, a technique that applies a glossy, raised effect to specific areas of a design. This is where Automatic Spot UV Coating Machines come into play, offering precision, efficiency, and consistency in applying this finishing touch.

In this blog, we’ll explore what an Automatic Spot UV Coating Machine is, how it works, and why it’s a game-changer for print businesses.

What is an Automatic Spot UV Coating Machine?

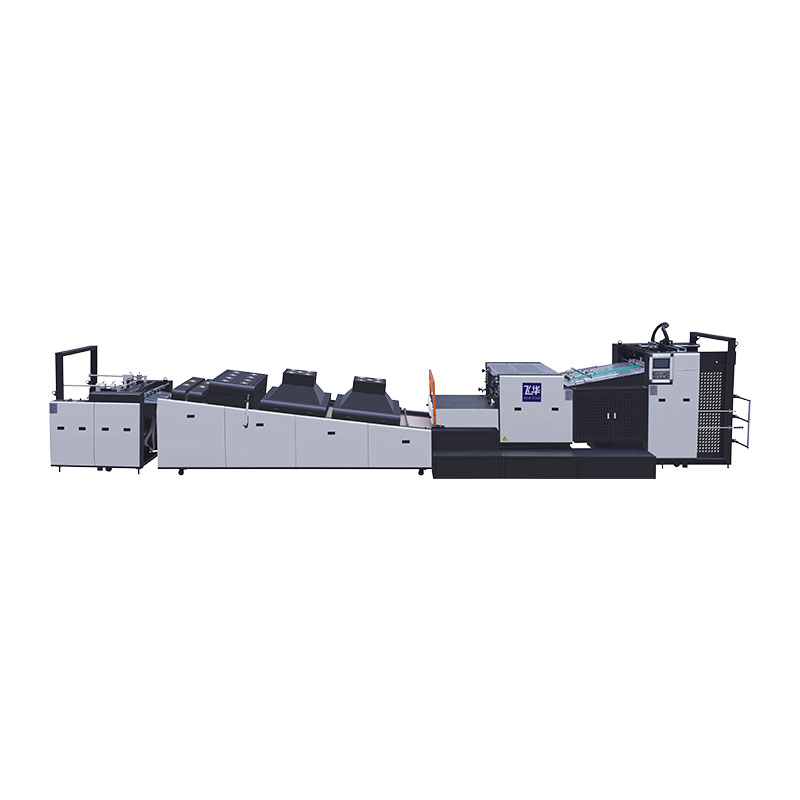

An Automatic Spot UV Coating Machine is a specialized piece of equipment designed to apply a clear, glossy UV coating to selective areas of a printed surface. Unlike full UV coating, which covers the entire page, spot UV coating enhances only specific design elements such as logos, images, or text, creating a striking contrast between matte and glossy areas.

This type of machine automates the process, ensuring consistent application while increasing production speed and reducing manual labor. It’s widely used in industries such as packaging, marketing, and high-end print production for business cards, brochures, book covers, and more.

How Does an Automatic Spot UV Coating Machine Work?

1. Preparation & Loading

- The printed sheets are placed into the feeder of the machine.

- A registration system ensures precise alignment for accurate UV coating application.

2. Coating Application

- The machine applies a special UV varnish to pre-selected areas of the design using a printing plate, digital inkjet technology, or a screen-printing method.

- The coating is spread evenly over the targeted sections, ensuring smooth coverage.

3. UV Curing

- After application, the coated areas pass under a UV light which instantly dries and hardens the coating, creating the glossy effect.

4. Final Output & Collection

- The finished sheets are collected, ready for further processing or packaging.

- Any excess UV varnish is automatically managed to minimize waste.

Key Benefits of Automatic Spot UV Coating Machines

1. Enhanced Visual Appeal

Spot UV coating adds a professional, premium look to printed materials. The contrast between matte and glossy areas creates a visually striking effect that grabs attention.

2. Precision & Consistency

Manual spot UV application can result in inconsistencies, but an automatic machine ensures precise alignment and even coating across every sheet.

3. Increased Efficiency

Automation speeds up production while maintaining quality, allowing businesses to handle large volumes of work with minimal downtime.

4. Cost Savings

By automating the UV coating process, companies can reduce labor costs and material waste, ultimately saving money while improving output.

5. Durability & Protection

Spot UV coating not only enhances aesthetics but also provides a protective layer that makes printed materials resistant to smudging, moisture, and general wear and tear.

Common Applications of Spot UV Coating

- Luxury Business Cards – Gives a sleek and sophisticated look with raised gloss effects.

- Brochures & Flyers – Highlights key design elements to capture attention.

- Book Covers – Adds texture and gloss to titles and logos.

- Packaging & Labels – Enhances branding on high-end product packaging.

- Presentation Folders – Elevates corporate materials with a premium finish.

An Automatic Spot UV Coating Machine is a must-have for businesses looking to add value to their printed materials while maintaining efficiency and quality. Whether you’re in the commercial printing industry or involved in high-end branding, this technology can help you create stunning, professional results that leave a lasting impression.