Understanding Auto Headlight PCBA Cloning - A Detailed Guide

2025-02-17

Auto headlight systems are crucial for vehicle safety, and their PCBA (Printed Circuit Board Assembly) is a key component in the lighting functionality. Cloning a headlight’s PCBA involves replicating its electronic design and functionality, which can be an exciting yet challenging project for electronics enthusiasts. In this blog, we will explore the process of PCBA cloning for auto headlights, the technical considerations involved, and what makes this task unique in the automotive sector.

What is PCBA Cloning?

PCBA cloning is the process of creating an exact or highly similar replica of a PCB used in a specific device. In the case of auto headlights, this involves reverse engineering the circuit board to match the design, layout, and components. It’s particularly useful for repairing headlights or creating aftermarket parts for vehicles.

The Process of Cloning Auto Headlight PCBA

1. Disassembly and Initial Analysis

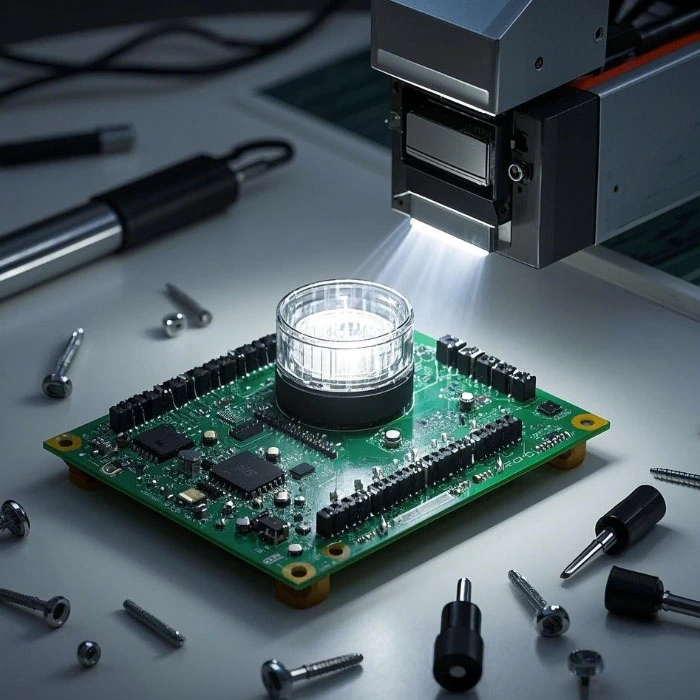

Before any cloning work begins, disassemble the headlight to expose the PCB. Carefully document the components, placements, and any identifying marks on the PCB. This is your blueprint for replication. Take note of specific features such as connectors, resistors, capacitors, and LEDs.

2. Reverse Engineering and Schematic Design

Once you have access to the PCB, you’ll need to reverse engineer it. This means analyzing the board’s layout and creating a schematic. Modern tools like Eagle and Altium can help you generate a schematic diagram from the board’s physical layout.

3. PCB Layout and Component Selection

After creating the schematic, the next step is to design the PCB layout. You must ensure that the cloned PCB matches the original in terms of trace routing, component placement, and electrical connections. Choosing the right components that replicate the performance of the original is essential.

4. Prototyping and Testing

Once the design is complete, the next step is to fabricate a prototype PCB. Testing is critical to ensure the cloned PCB functions just like the original. This may involve functional testing in the vehicle's headlight system to ensure performance standards are met.

Challenges in Auto Headlight PCBA Cloning

- Environmental Durability: Headlight PCBs must endure harsh conditions like heat, moisture, and vibration. Your cloned PCB must be designed to handle these challenges.

- Legal and Ethical Concerns: Cloning an auto headlight’s PCBA could have intellectual property implications, especially if it involves a patented design. Always ensure that you are not violating any patents or regulations when cloning.

- Component Availability: Auto headlights often use specialized components, so finding exact replacements may be tricky. Ensure you can source compatible parts to achieve the same functionality.

Cloning an auto headlight PCBA is an intricate and rewarding process that requires patience and expertise in electronics. With the right tools and knowledge, it’s possible to create a functioning clone that performs like the original, whether for repairs or custom applications. Keep in mind that understanding the technical aspects of the design and addressing the challenges head-on will ensure a successful project.