The Crucial Role of Bearings in Large Diameter Stringing Blocks

2024-05-15

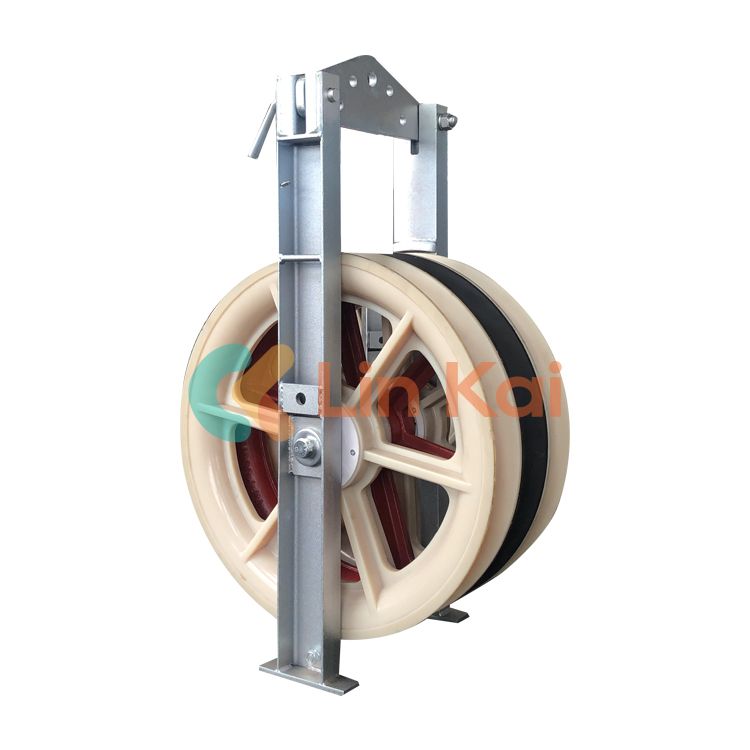

In the world of power line construction and maintenance, large diameter stringing blocks are indispensable tools that guide conductors with precision. At the heart of these blocks lies a critical component: the bearings. While often overlooked, bearings play a crucial role in ensuring the smooth and efficient operation of stringing blocks. Let's explore the significance of bearings in large diameter stringing blocks and how they contribute to the success of power line projects.

1. Facilitating Smooth Rotation

Role: Bearings enable the sheaves, or wheels, of large diameter stringing blocks to rotate smoothly.

Importance: Smooth rotation is essential for guiding the conductor without causing unnecessary friction or stress. Bearings ensure that the sheaves move freely, reducing wear and tear on both the conductor and the block itself.

2. Load Distribution

Role: Bearings distribute the load evenly across the sheaves and axles.

Importance: In stringing operations, the conductor may exert significant forces on the stringing block. Bearings help distribute these loads evenly, preventing localized stress points that could lead to premature failure. This ensures the stability and integrity of the stringing block under varying loads.

3. Minimizing Friction

Role: Bearings reduce friction between moving parts, such as the sheaves and axles.

Importance: Friction generates heat and can cause premature wear on the components of the stringing block. By minimizing friction, bearings help maintain the efficiency and longevity of the block, ensuring smooth operation over time.

4. Absorbing Shock and Vibration

Role: Bearings absorb shock and dampen vibration during stringing operations.

Importance: Stringing blocks may experience shocks and vibrations from various sources, such as the movement of the conductor or external forces. Bearings act as shock absorbers, reducing the impact on the block and preventing damage or instability. This enhances the safety and reliability of the stringing process.

5. Supporting Axial and Radial Loads

Role: Bearings support both axial (parallel to the axis) and radial (perpendicular to the axis) loads.

Importance: Large diameter stringing blocks may experience forces from multiple directions during operation. Bearings are designed to withstand these loads, providing stability and ensuring that the block can perform effectively under varying conditions.

6. Corrosion Resistance

Role: Bearings in stringing blocks are often made from corrosion-resistant materials.

Importance: Power line construction and maintenance often take place in harsh environments where exposure to moisture, chemicals, and other corrosive agents is common. Bearings made from corrosion-resistant materials, such as stainless steel or sealed bearings, help protect the block from premature deterioration, ensuring long-term reliability.

Conclusion

In the intricate world of power line construction, every component plays a vital role in ensuring the success and safety of the operation. Bearings in large diameter stringing blocks are no exception. From facilitating smooth rotation and distributing loads to minimizing friction and absorbing shock, bearings are integral to the efficient functioning of stringing blocks.

By understanding the crucial role bearings play and ensuring their proper maintenance and selection, power line professionals can maximize the performance and lifespan of their stringing blocks. With reliable bearings at their core, large diameter stringing blocks continue to guide conductors safely and efficiently, contributing to the seamless delivery of electricity to communities around the world.