Primary Applications of Metalworking Bronze Sintering Grinding Wheels in Industrial Settings

2024-07-04

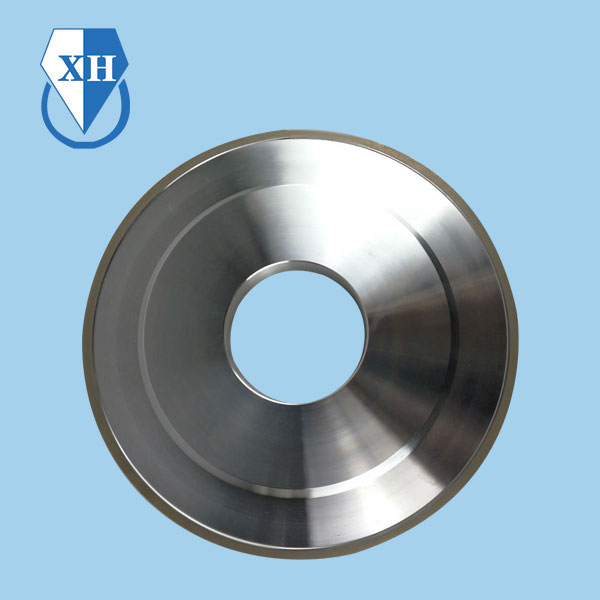

In the world of industrial manufacturing, precision and efficiency are paramount. Among the many tools that help achieve these goals, the metalworking bronze sintering grinding wheel stands out for its unique properties and versatility. This specialized grinding wheel is crafted through a process of sintering, where bronze and abrasive materials are fused together under high temperatures and pressure. The result is a highly durable and effective tool used across various industrial applications. In this blog, we will explore the primary applications of metalworking bronze sintering grinding wheels in industrial settings.

1. Precision Grinding

One of the most significant applications of metalworking bronze sintering grinding wheels is in precision grinding. These wheels are used to achieve high levels of accuracy and smooth finishes on metal surfaces. Industries such as aerospace, automotive, and medical device manufacturing rely on precision grinding to produce components that meet stringent specifications. The bronze sintering grinding wheel’s ability to maintain its shape and sharpness over time makes it ideal for these tasks.

2. Tool and Die Making

Tool and die making is another area where metalworking bronze sintering grinding wheels are indispensable. This process involves creating molds, dies, and tools used in manufacturing other parts. The durability and precision of bronze sintering grinding wheels allow for the meticulous shaping and finishing required in this field. They can grind hardened tool steels and other tough materials with ease, ensuring that the finished tools and dies have the necessary accuracy and surface quality.

3. Surface Grinding

Surface grinding is a common industrial application where metalworking bronze sintering grinding wheels excel. This process involves removing material from the surface of a workpiece to create a smooth, flat finish. Surface grinding is used in the production of flat plates, machine components, and other parts that require a precise surface finish. The bronze sintering grinding wheel’s ability to produce a consistent finish without excessive wear makes it a preferred choice for this application.

4. Cylindrical Grinding

In cylindrical grinding, metalworking bronze sintering grinding wheels are used to grind the external or internal surfaces of cylindrical workpieces. This process is essential in the production of shafts, rods, and other cylindrical components. The wheels’ toughness and wear resistance ensure that they can handle the continuous grinding required to produce these parts with the necessary precision and finish.

5. Centerless Grinding

Centerless grinding is a specialized technique used to grind the outer diameter of cylindrical workpieces without using a center fixture. Metalworking bronze sintering grinding wheels are particularly well-suited for this method due to their ability to maintain their shape and cutting efficiency over extended use. This application is critical in the mass production of small, precise components such as automotive parts, bearings, and fasteners.

6. Creep-Feed Grinding

Creep-feed grinding is a deep grinding process where a large amount of material is removed in a single pass at a slow feed rate. This technique is used to create intricate shapes and profiles in hard materials. Metalworking bronze sintering grinding wheels are ideal for creep-feed grinding due to their high material removal rate and resistance to heat and wear. Industries such as aerospace and power generation use this process to manufacture turbine blades, gears, and other complex components.

7. Sharpening and Reconditioning

Sharpening and reconditioning of cutting tools and other industrial equipment is another key application for metalworking bronze sintering grinding wheels. These wheels can restore the sharpness and functionality of tools such as drill bits, saw blades, and milling cutters. The wheels’ ability to produce a precise edge and maintain their integrity over multiple sharpening cycles makes them an essential tool in maintenance and reconditioning operations.

8. Heavy-Duty Grinding

For heavy-duty grinding applications, such as removing large amounts of material or working with exceptionally hard metals, metalworking bronze sintering grinding wheels provide the necessary durability and cutting power. Industries like shipbuilding, heavy machinery, and construction often require robust grinding solutions to handle large-scale projects and tough materials. The resilience and effectiveness of bronze sintering grinding wheels make them a go-to choice for these demanding tasks.

Conclusion

Metalworking bronze sintering grinding wheels are a versatile and essential tool in various industrial applications. Their ability to deliver precision, durability, and efficiency makes them invaluable in fields such as aerospace, automotive, tool and die making, and heavy-duty manufacturing. By understanding the primary applications of these specialized grinding wheels, industries can better leverage their benefits to enhance production processes and achieve high-quality results.