How Does the ZJS716 Multi-Axis Control System Improve Laser Processing Efficiency?

2025-06-26

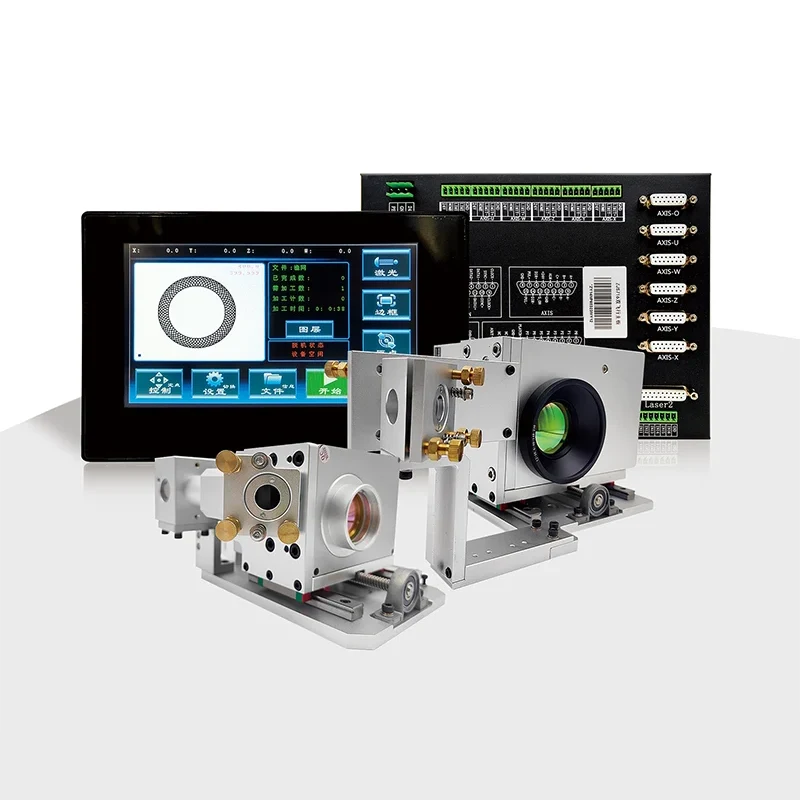

In the evolving world of laser processing, manufacturers constantly face increasing demands for precision, speed, and versatility. The ZJS716 Multi-Axis Linkage Control System has emerged as a powerful solution that breaks through the limitations of conventional equipment, offering a new benchmark for integrated cutting and engraving performance across various industries.

At its core, the ZJS716 is designed to coordinate the X and Y axes of both the frame movement and the galvanometer system, creating a seamless four-axis linkage that ensures precise, synchronized control. This advanced coordination enables multi-axis linkage operation, significantly enhancing the stability and accuracy of laser processing tasks. With this system, manufacturers can expect ultra-high precision and processing speeds that are five to ten times faster than traditional cutting methods, directly improving production efficiency and reducing operational costs.

The ZJS716 system also incorporates intelligent visual recognition and automatic positioning, ensuring that materials are accurately aligned for each task. Its high-speed galvanometer system combined with precise adjustment capabilities further guarantees clean, accurate results, whether for intricate engraving or high-speed cutting. The stable frame structure minimizes mechanical deviation, contributing to consistent, reliable output even under demanding production conditions.

One of the standout features of the ZJS716 is its ability to support automatic switching between cutting and engraving, eliminating the need for manual intervention and enhancing workflow efficiency. The integrated self-check and intelligent correction functions of the galvanometer system ensure consistent performance over extended operation periods, reducing maintenance requirements and maximizing uptime.

To simplify operation, the ZJS716 features a user-friendly seven-inch touchscreen interface, allowing intuitive control over the entire process. With one-click graphic import and parameter adjustment, even complex setups can be executed efficiently, lowering the learning curve for new operators and accelerating production transitions.

For industries where production continuity and quality cannot be compromised, the ZJS716 Multi-Axis Linkage Control System represents a significant technological advancement. It integrates intelligent functions such as multi-head synchronous processing and cutting conversion, minimizing manual operations and optimizing workflow. With its combination of speed, precision, and adaptability, the ZJS716 provides a comprehensive solution for modern manufacturers seeking to elevate their laser processing capabilities to new heights.