Exploring the Core Components of the Intelligent Factory Supply Automated Edge Banding Cell

2024-03-15

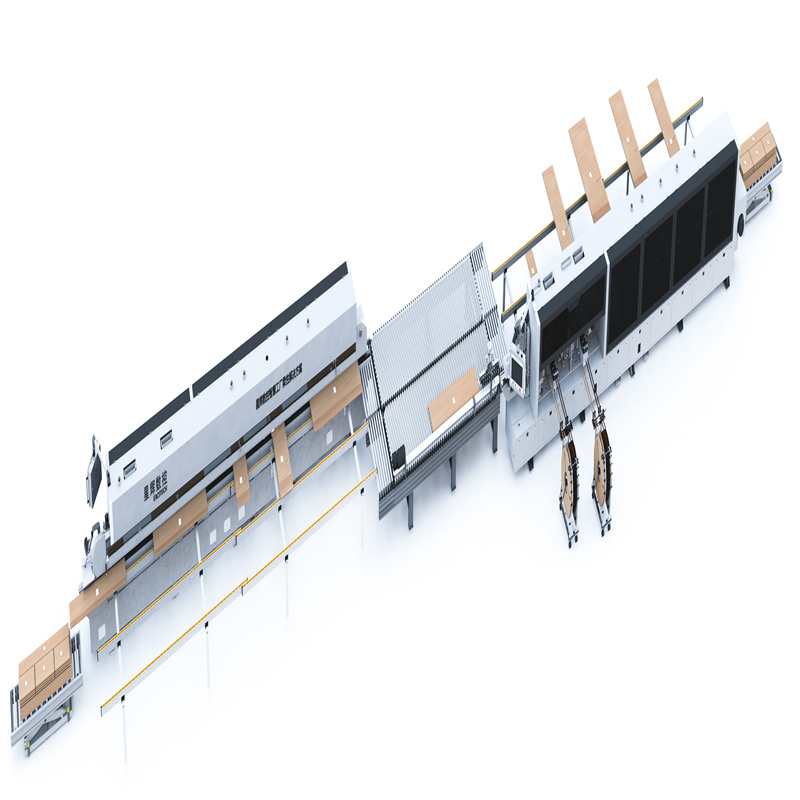

In the ever-evolving landscape of manufacturing, advancements in automation and technology continue to revolutionize production processes, driving efficiency, precision, and innovation. One such example is the Intelligent Factory Supply Automated Edge Banding Cell, a sophisticated system designed to streamline edge banding operations in woodworking and furniture manufacturing. In this blog, we delve into the primary components of this cutting-edge solution, uncovering the key elements that contribute to its efficiency and effectiveness in modern manufacturing environments.

1. Edge Banding Machine:

At the heart of the Intelligent Factory Supply Automated Edge Banding Cell lies the edge banding machine itself. This machine is equipped with advanced technology to apply edge banding material – such as PVC, ABS, or wood veneer – onto the edges of workpieces with precision and consistency. It features conveyor systems, heating elements, glue application mechanisms, and trimming units to ensure seamless edge banding operations.

2. Automated Material Handling System:

Efficient material handling is essential for optimizing production workflows. The Intelligent Factory Supply Automated Edge Banding Cell incorporates an automated material handling system to transport workpieces to and from the edge banding machine seamlessly. This system may include conveyor belts, robotic arms, or gantry systems, controlled by sophisticated software to coordinate material flow and maximize throughput.

3. Vision System:

Precision and accuracy are paramount in edge banding operations, and a vision system plays a crucial role in achieving these objectives. Utilizing cameras and sensors, the vision system precisely identifies workpiece dimensions, edge profiles, and alignment requirements, enabling the edge banding machine to apply banding material with pinpoint accuracy.

4. CNC Machining Center (Optional):

In some configurations, the Intelligent Factory Supply Automated Edge Banding Cell may include a CNC machining center as part of its integrated workflow. This addition allows for further processing of workpieces, such as drilling holes, cutting grooves, or shaping profiles, to meet specific design requirements before edge banding.

5. Software and Control Systems:

Behind the scenes, sophisticated software and control systems orchestrate the operation of the Intelligent Factory Supply Automated Edge Banding Cell. These systems manage material flow, coordinate machine movements, monitor production metrics, and provide real-time feedback to operators. Additionally, they may incorporate machine learning algorithms or artificial intelligence to optimize performance and adapt to changing production demands.

6. Quality Assurance Tools:

Ensuring the quality of finished products is essential in manufacturing, and the Intelligent Factory Supply Automated Edge Banding Cell is equipped with quality assurance tools to uphold high standards. These may include sensors for detecting defects or inconsistencies in edge banding material, as well as automated inspection systems to verify the accuracy of edge banding application.

7. Connectivity and Integration Capabilities:

To seamlessly integrate into modern manufacturing environments, the Intelligent Factory Supply Automated Edge Banding Cell features connectivity and integration capabilities. It can communicate with other machines, manufacturing systems, and enterprise software platforms, enabling data exchange, production scheduling, and remote monitoring for enhanced efficiency and control.

In conclusion, the Intelligent Factory Supply Automated Edge Banding Cell represents a significant advancement in edge banding technology, combining precision, automation, and intelligence to streamline manufacturing processes. By incorporating edge banding machines, automated material handling systems, vision systems, CNC machining centers (optional), software and control systems, quality assurance tools, and connectivity capabilities, this innovative solution offers a comprehensive approach to edge banding operations, setting new standards for efficiency and productivity in the woodworking and furniture manufacturing industry.