Crafting Excellence: Key Characteristics of a High-Quality Bathroom Chassis Mould

2023-11-13

Introduction:

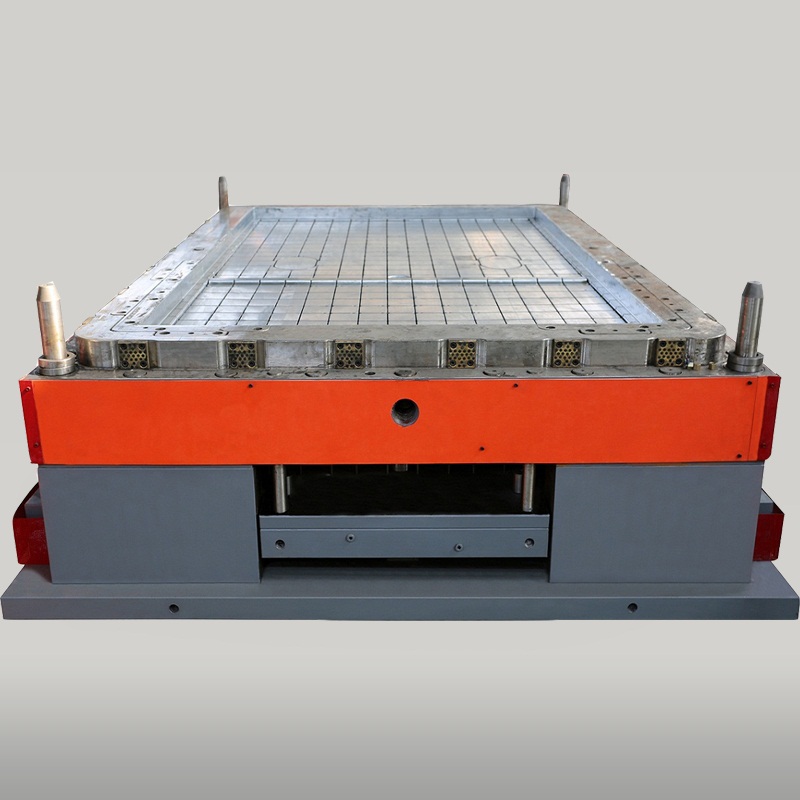

In the realm of bathroom manufacturing, precision and quality are paramount. At the core of this process lies the bathroom chassis mould, a crucial element that shapes the final product's form and functionality. In this blog, we delve into the key characteristics that define a high-quality bathroom chassis mould, emphasizing the importance of these features in the production of superior bathroom components.

1. Precision in Design:

A hallmark of a high-quality bathroom chassis mould is the precision in its design. Every contour, angle, and dimension is meticulously crafted to ensure the accurate reproduction of the desired bathroom component. Precision is not only crucial for visual appeal but also for the seamless integration of the final product into the bathroom space.

2. Durable Material Selection:

The choice of materials used in constructing a bathroom chassis mould significantly influences its durability. High-quality moulds are often crafted from robust materials that can withstand the stress and pressure of repeated molding cycles without compromising on structural integrity. This durability contributes to the mould's longevity and reliability in the manufacturing process.

3. Optimal Cooling System:

Efficient cooling is a key factor in the production of bathroom components. A high-quality chassis mould incorporates an optimal cooling system that regulates temperature during the molding process. This not only enhances the speed of production but also minimizes the risk of defects, ensuring each molded piece meets the desired specifications.

4. Surface Finish Excellence:

The surface finish of a bathroom chassis mould is a critical aspect that directly impacts the final appearance of the molded product. High-quality moulds feature a superior surface finish, resulting in bathroom components with smooth, flawless surfaces. This attention to detail contributes to the overall aesthetic appeal of the final product.

5. Venting Systems for Quality Assurance:

To prevent defects such as air pockets or incomplete fills, high-quality bathroom chassis moulds are equipped with effective venting systems. These systems ensure that air is properly evacuated during the molding process, promoting a consistent and defect-free finish in the molded components.

6. Compliance with Standards:

Adherence to industry standards and regulations is a non-negotiable characteristic of a high-quality bathroom chassis mould. Manufacturers must ensure that their moulds meet or exceed established standards to guarantee the safety, reliability, and consistency of the produced bathroom components.

7. Customization Capabilities:

Flexibility and adaptability are key features of high-quality bathroom chassis moulds. The ability to customize moulds according to the unique requirements of different bathroom component manufacturers ensures versatility and broad market applicability.

8. Minimal Shrinkage and Warping:

Quality bathroom chassis moulds are designed to minimize issues related to shrinkage and warping during the molding process. This ensures that the final products maintain their intended dimensions and structural integrity, meeting the highest standards of quality and performance.

Conclusion:

In the world of bathroom manufacturing, a high-quality chassis mould is the unsung hero that shapes the form and function of the final product. The meticulous attention to precision in design, choice of durable materials, optimal cooling systems, superior surface finishes, effective venting, compliance with standards, customization capabilities, and the prevention of shrinkage and warping collectively define a bathroom chassis mould of exceptional quality. Manufacturers investing in these characteristics not only elevate the quality of their products but also contribute to the overall excellence of the bathroom industry.