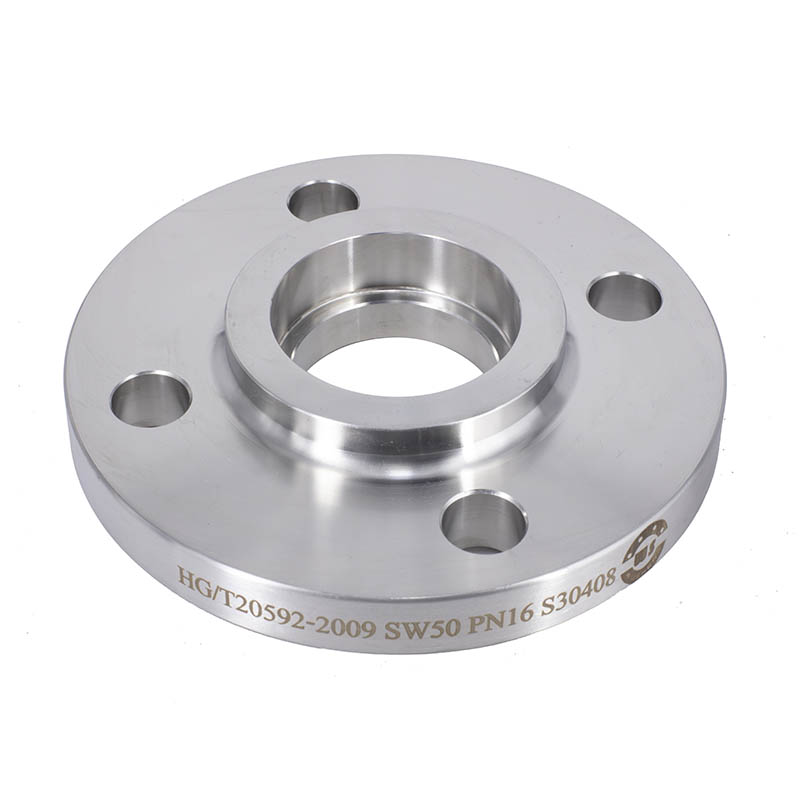

Unveiling the Strength and Versatility of Duplex Steel S31803 Socket Weld Flanges

2023-10-18

Introduction

In the world of piping and industrial applications, choosing the right components is critical to ensuring longevity, strength, and resistance to corrosion. Duplex steel, particularly the S31803 grade, is a standout material renowned for its exceptional properties. Among the various components made from duplex steel, S31803 socket weld flanges deserve special attention. In this blog, we will explore these remarkable flanges, their features and benefits, and the extensive range of applications where they excel.

The Essence of Duplex Steel S31803

Duplex stainless steel is a family of materials known for their unique combination of austenitic and ferritic microstructures. S31803, a specific grade within the Duplex family, contains approximately 22% chromium, 5-6% nickel, and 3% molybdenum. This composition imparts remarkable properties that make it ideal for a variety of applications.

The Strengths of Duplex Steel S31803 Socket Weld Flanges

1. Corrosion Resistance: Duplex steel S31803 is highly resistant to corrosion, making it suitable for use in a wide range of environments, including those exposed to moisture, saltwater, and aggressive chemicals.

2. Strength and Durability: These flanges are renowned for their mechanical strength, ensuring that they can withstand high pressures and stress without deformation or failure.

3. Versatility: S31803 socket weld flanges are versatile and suitable for various industries, including oil and gas, chemical processing, and offshore applications, thanks to their resistance to both pitting and crevice corrosion.

4. Cost-Effective: While duplex steel may have a higher initial cost compared to some other materials, its durability and longevity result in long-term cost savings due to reduced maintenance and replacement needs.

Applications of Duplex Steel S31803 Socket Weld Flanges

1. Oil and Gas Industry: These flanges are extensively used in the oil and gas sector for both offshore and onshore applications. Their resistance to chloride-induced stress corrosion cracking (SCC) is particularly valuable in marine environments.

2. Chemical Processing: Duplex steel S31803 Socket Weld Flanges are preferred in chemical plants where exposure to aggressive chemicals is common. The combination of corrosion resistance and strength makes them a reliable choice for transporting various chemicals.

3. Desalination Plants: These flanges are favored in desalination facilities due to their ability to withstand the corrosive effects of saltwater and maintain the purity of fresh water production.

4. Petrochemical Industry: Used in the transportation of petroleum products and in processing units where their strength and corrosion resistance are highly valued.

5. Renewable Energy: Duplex steel S31803 Socket Weld Flanges are also utilized in renewable energy applications, such as wind and solar power projects, where their resistance to harsh weather conditions and durability are essential.

Conclusion

Duplex steel S31803 Socket Weld Flanges are a testament to the strength and versatility of modern materials in the world of industrial piping. Their exceptional corrosion resistance, mechanical strength, and adaptability to various industries make them an ideal choice for critical applications. When reliability, longevity, and performance are paramount, S31803 Socket Weld Flanges stand out as a solid and dependable solution for any piping project, ensuring the integrity of systems in demanding environments. Choosing S31803 flanges is not just a choice; it's an investment in the long-term success of your industrial projects.